What to know before investing in a stretch wrapping machine

What to know before investing in a stretch wrapping machine

Blog Article

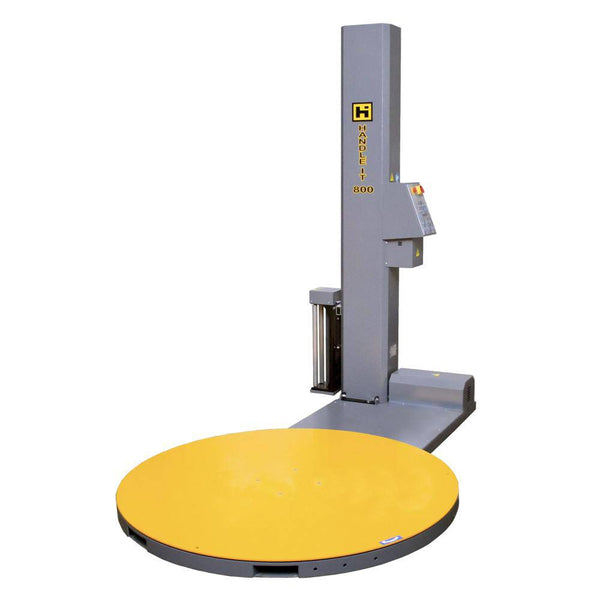

Make Best Use Of Lots Stability With an Advanced Stretch Wrapping Maker for Safe Transportation

In the realm of secure transport, making the most of load stability preponderates. Advanced stretch covering makers use an ingenious remedy, wrapping up lots with determine accuracy to avoid shifting throughout transit. With a collection of features such as adjustable film tension and automated capability, these equipments supply regular vertical and straight security while minimizing damages risk. Making use of slit and tear-resistant stretch movie, companies can feel confident their products will certainly arrive intact. But how do these machines precisely improve lots stability and efficiency? Let's discover.

Comprehending the Role of Stretch Covering in Safe Transportation

While several may neglect its value, stretch wrapping plays an important function in making certain the secure transportation of goods. This procedure includes the use of an extremely elastic plastic film that is wrapped around things, typically on a pallet. The elastic recovery of the wrap firmly protects the things with each other, protecting against motion during transportation.

Secret Features of Advanced Stretch Wrapping Machines

In the world of logistics and supply chain management, advanced stretch covering makers have emerged as a game-changer. These devices are defined by numerous essential functions that identify them from their predecessors.

Advanced stretch wrapping devices additionally feature pre-stretch capacities. This function allows the film to be lengthened prior to being used to the tons, optimizing movie usage and minimizing prices. Additionally, these makers have flexible controls for film tension, allowing modification based on load size and shape.

Ultimately, these equipments are furnished with integrated lots cells, which precisely determine the weight of the tons during the wrapping process. This feature ensures the machine changes its procedure based upon the weight, therefore stopping damages and guaranteeing the tons's secure transportation. Thus, progressed stretch wrapping equipments use a mix of automation, safety, efficiency, and cost-effectiveness.

How Stretch Wrapping Machines Enhance Load Security

Guaranteeing that tons stay steady during transport is a vital facet of logistics, and one that progressed stretch wrapping makers master dealing with. These equipments function by covering the lots in a protective film that holds all items firmly together. This minimizes the risk of products dropping or moving throughout transportation, therefore boosting load stability.

The devices employ an innovative covering strategy that provides not only upright but additionally horizontal security. This dual-axis stability better enhances the lots and lowers the chance of damage or loss. The consistent stress used by the maker throughout the wrapping process guarantees that the lots is small and safe and secure.

Prospective Price Cost Savings With Effective Stretch Covering

Beyond improving lots stability, progressed stretch covering machines additionally use considerable potential for expense financial savings. These equipments lower the demand for manual our website labor, thus decreasing pay-roll expenditures. They additionally function faster and a lot more effectively than human beings, leading to have a peek at these guys enhanced productivity.

The usage of advanced equipments makes certain ideal usage of stretch movie, which can lead to significant financial savings in material prices. Hand-operated wrapping usually causes wastage because of irregular use of film. A maker uses the right quantity of movie, removing wastage.

In addition, the improved tons security reduces the danger of damages during transport. This can possibly save services from expensive item losses and connected replacement prices.

Finally, the equipments require marginal maintenance, which equates into lower repair and upkeep prices.

Picking the Right Stretch Covering Equipment for Your Organization Demands

While the advantages of sophisticated stretch covering devices are obvious, choosing the right one for your details company demands can be a challenging job. Various aspects require to be taken into consideration - stretch wrapping machine. Consider the kind and volume of items to be wrapped. Equipments vary in ability and adjustability to wrap various dimensions and forms of lots. Secondly, examine the rate requirements of your operation. High-volume operations would profit from automatic machines with higher speeds, while semi-automatic devices might be sufficient for smaller sized services. Think about the device's longevity and upkeep requirements. A durable device that needs marginal upkeep might save expenses in the future. Lastly, take into consideration the equipment's integration with your existing production line. It must enhance, not disrupt, your workflow. A complete examination of these aspects can assist services in the direction of the optimum stretch wrapping device, hence making sure safe transport of their items.

Verdict

In verdict, progressed stretch covering equipments are crucial in making sure load stability throughout transportation. Businesses must consider investing in an ideal stretch covering equipment, further enhancing safety and security and efficiency within their supply useful reference chain.

Advanced stretch covering machines use an innovative service, wrapping up loads with identify precision to prevent changing throughout transportation.Ensuring that loads continue to be stable during transport is a crucial element of logistics, and one that progressed stretch covering devices stand out in resolving.Beyond enhancing load security, advanced stretch covering equipments also provide substantial possibility for price financial savings. High-volume procedures would certainly profit from automated devices with greater speeds, while semi-automatic makers may be enough for smaller sized services.In final thought, advanced stretch wrapping equipments are vital in making sure load security during transport.

Report this page